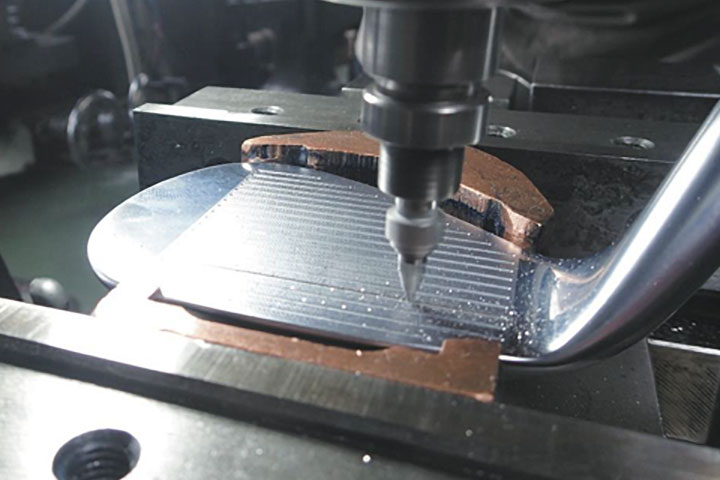

THE CHALLENGE OF

HIKONE FACTORY

TSURUYA GOLF’s Hikone Factory in Shiga Prefecture, marked out by the blue name-board

visible from the carriage windows on the Tokaido Shinkansen line,

manages the production of

original clubs and customizes and repairs clubs left at our shops by customers.

To satisfy customers’ requests and maximize the capabilities of golfers,

we are pursuing the highest quality clubs with the techniques and accumulated experience of

our staff.